How to Maintain and Clean Large-Scale Kitchen Equipment Efficiently

Efficient cleaning and maintenance practices help kitchen staff save time and meet compliance standards.

Maintaining and cleaning large-scale kitchen equipment is a

critical aspect of running a successful commercial kitchen. From ovens to

refrigerators and dishwashers, these pieces of equipment form the backbone of

daily operations, and their cleanliness and functionality are paramount.

Regular upkeep not only ensures food safety and hygiene but also extends the

life of the equipment, reducing costly breakdowns. Efficient cleaning and maintenance

practices help kitchen staff save time and meet compliance standards.

The first step in maintaining large-scale kitchen equipment is understanding the manufacturer’s guidelines. Most equipment comes with specific instructions on cleaning frequency, suitable cleaning agents, and maintenance procedures. Adhering to these guidelines ensures that the equipment is cared for properly without voiding warranties. For example, steam ovens require regular descaling, while gas ranges often need burner checks. A well-trained team familiar with these instructions can significantly improve cleaning efficiency and equipment longevity.

Regular cleaning schedules should be established to avoid dirt and grease buildup, which can lead to operational inefficiencies and even equipment failures. Daily cleaning routines are essential for high-use equipment like grills, ovens, and fryers. For instance, wiping down surfaces after each shift and cleaning detachable parts can prevent grease accumulation. Weekly or monthly deep cleaning should address areas less accessible during daily cleaning, such as behind the equipment or internal components.

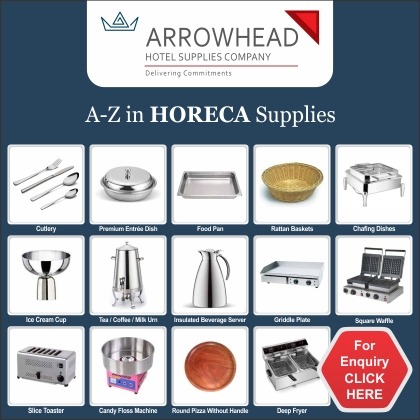

Investing in the right cleaning tools and supplies is crucial for efficient maintenance. Heavy-duty degreasers, non-abrasive scrubbers, and microfiber cloths can help clean surfaces without causing damage. Additionally, specialized equipment like pressure washers or steam cleaners can be highly effective for deep-cleaning tasks, such as removing stubborn grime from range hoods or floor-mounted equipment. Using tools tailored to the specific needs of the kitchen reduces cleaning time while ensuring thorough results.

Proper training for staff members is another essential component of efficient kitchen equipment maintenance. All staff should be familiar with the basic cleaning protocols for each piece of equipment they use. Cross-training ensures that responsibilities are shared, preventing bottlenecks in the cleaning schedule. Additionally, educating staff on recognizing signs of wear and tear, such as unusual noises or temperature fluctuations, can help address potential issues before they escalate into major problems.

Preventive maintenance is equally as important as cleaning. Scheduling regular inspections by qualified technicians can identify hidden problems and prevent equipment breakdowns. For example, refrigeration units require periodic checks for coolant levels and door seals, while dishwashers may need inspections for water pressure and drainage efficiency. Preventive maintenance ensures that all equipment operates at peak efficiency and minimizes unexpected disruptions during busy service hours.

Another effective strategy is organizing the kitchen layout to support efficient cleaning. Equipment should be positioned to allow easy access for routine maintenance and cleaning. For example, leaving sufficient space between appliances and walls makes it easier to clean behind and underneath heavy units. Mobile or easily disassembled equipment is particularly advantageous, as it allows staff to clean hard-to-reach areas without excessive effort.

Energy efficiency should also be considered during maintenance. Dirty equipment tends to consume more energy, increasing operational costs. For example, a dirty condenser coil in a refrigerator can force the unit to work harder, leading to higher electricity usage. Regular cleaning of these components ensures energy efficiency and keeps utility bills under control, contributing to the overall sustainability of the kitchen.

Documentation plays a vital role in maintaining a consistent and efficient cleaning routine. A detailed cleaning and maintenance log helps keep track of completed tasks, scheduled deep cleanings, and equipment inspections. This not only ensures accountability among staff but also provides valuable records for health inspections and audits. Digital tools or apps designed for kitchen management can further streamline this process by setting reminders and organizing records.

Lastly, using eco-friendly cleaning methods wherever possible aligns with sustainable kitchen practices. Biodegradable cleaning agents and water-saving techniques reduce environmental impact without compromising hygiene standards. Moreover, sustainability practices resonate with modern diners, enhancing the reputation of the business.

Maintaining and cleaning large-scale kitchen equipment efficiently involves a combination of regular cleaning, preventive maintenance, proper training, and organization. By adhering to these principles, commercial kitchens can operate smoothly, maintain high hygiene standards, and extend the lifespan of essential equipment. These practices ensure not only the functionality of the kitchen but also the satisfaction of staff and guests alike.

.png)