SHARE

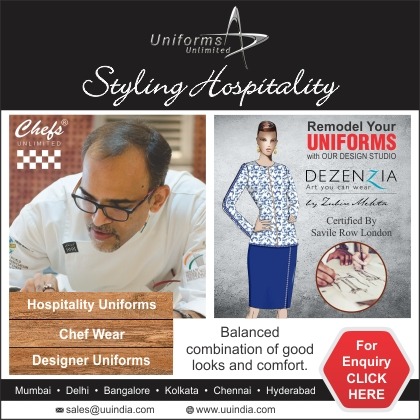

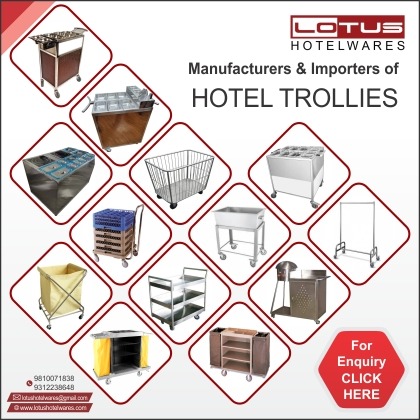

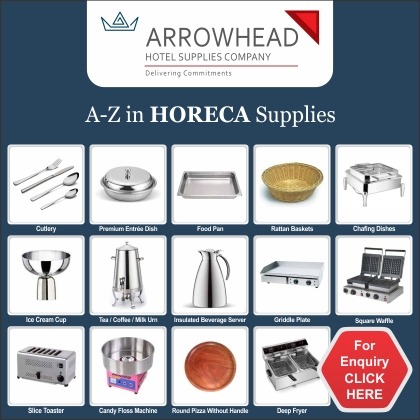

Commercials

More Posts

May 22, 2025

Malai Kofta - By Neelam Garg

Jan 30, 2025

Vegan Ravioli - By Chef Manoj Rathore

May 22, 2025

Malai Kofta - By Neelam Garg

Jan 30, 2025

Vegan Ravioli - By Chef Manoj Rathore

May 22, 2025

.png)